HP41C Printer Works

When I bought my HP41C, it came with a printer. The batteries were dead, so I threw them out and bought some tagged cells. I left it at that as I wasn't sure what the wiring of the battery packs were. Anyway, this morning I decided to have a look inside and see if I could get it going. The wiring was straightforward, so I attached the battery pack. I don't know what sort of charger it uses, so looking at the components, I guessed about 6V a.c (as there is a bridge rectifier in there). I attached a supply and the batteries seem to charge. I'll have to invesigate that.

Anyway I turned the printer on and attached it to the HP41C, but nothing much happened. i was about to give up when I noticed that a wire was hanging off a connector. I soldered it on and more life appeared in the printer. Anyway, it turned out that several more wires had broken, so I soldered them all, and we have this:

The printer prints. It also takes standard thermal paper so that's obtainable. It makes the HP41C even more of a nice little machine.

I'll have to tidy up the wiring and printer physical arrangement, but it looks like this will work again.

Saturday, 23 January 2016

Tripod Fixed

I've printed two new clamps for the broken tripod, and after a couple of iterations of both, I have a working tripod again:

I've used bolts and nyloc nuts to hold the clamp lever on to the part, so I don't have to hammer the brass rod into the part, as I broke a lot of the printed parts that way. It still works, it's a bit larger than the original, but it is now able to be dismantled.

Wednesday, 20 January 2016

Lamp Cover Replacement

A friend asked me if I could create a replacement lamp cover for a washing machine. One of the clips holding it in has broken off:

It took about an hour to come up with an OpenSCAD model of the cover and I printed a test part in clear PLA. There's some support material shown here on one of the clips, this was useful as there was a bit of overhang on that clip.

I have some translucent orange filament, at least I hope I have enough, as it came from a pack of various colours. I'll print an orange one when the design works. I have filed it down a bit to tidy up where the support material attached, and to reduce the size of the clips a bit. It compares quite well with the original:

Lamp cover in use:

A friend asked me if I could create a replacement lamp cover for a washing machine. One of the clips holding it in has broken off:

It took about an hour to come up with an OpenSCAD model of the cover and I printed a test part in clear PLA. There's some support material shown here on one of the clips, this was useful as there was a bit of overhang on that clip.

I have some translucent orange filament, at least I hope I have enough, as it came from a pack of various colours. I'll print an orange one when the design works. I have filed it down a bit to tidy up where the support material attached, and to reduce the size of the clips a bit. It compares quite well with the original:

Lamp cover in use:

Monday, 18 January 2016

Commodore N60

To go with the S61, recently got an N60:

Batteries had to be replaced, then I found that the display had bad ghosting. With the S61 I added a resistor to drag the display down in voltage a bit, which seemed to work. This time I looked at the PCB and found some deposits from the battery leakage. After cleaning them off the display looked like this:

Tripod Fixing

I bought a Manfrotto tripod ages ago and used it now and then. It's quite a nice smaller one that isn't too much of a pain to carry about. Unfortunately it fell over somewhere ( I forget where) and it broke. At the time I didn't have a 3D printer so fixing the plastic part that had broken wasn't really an option. Last weekend we went to the London Lumiere displays and I thought of using a tripod again as all the displays were turned on after dark. In the end I didn't use one, and got some interesting photos anyway.

I decided to have a go at fixing the tripod as it was useful now and again and would be a shame to throw away. So, after some OpenSCAD and printing I have this:

This is the clamp that broke attached to the tripod leg. I've got a drill bit temporarily holding it all together as the original fixing of the handle was done by hammering the brass rod into the handle. This is a pain and I've broken a couple of plastic fitting this way. If the only broken poart was this one then I'd be done at this point, but when I was trying to dismantle the leg I needed to take another part off, and hammering the brass rod out resulted in the plastic part cracking. So now I have to fix another part (slightly larger so I can't use the first design).

Anyway, the clamp seems to work OK, so the fix looks like it may work...

I bought a Manfrotto tripod ages ago and used it now and then. It's quite a nice smaller one that isn't too much of a pain to carry about. Unfortunately it fell over somewhere ( I forget where) and it broke. At the time I didn't have a 3D printer so fixing the plastic part that had broken wasn't really an option. Last weekend we went to the London Lumiere displays and I thought of using a tripod again as all the displays were turned on after dark. In the end I didn't use one, and got some interesting photos anyway.

I decided to have a go at fixing the tripod as it was useful now and again and would be a shame to throw away. So, after some OpenSCAD and printing I have this:

This is the clamp that broke attached to the tripod leg. I've got a drill bit temporarily holding it all together as the original fixing of the handle was done by hammering the brass rod into the handle. This is a pain and I've broken a couple of plastic fitting this way. If the only broken poart was this one then I'd be done at this point, but when I was trying to dismantle the leg I needed to take another part off, and hammering the brass rod out resulted in the plastic part cracking. So now I have to fix another part (slightly larger so I can't use the first design).

Anyway, the clamp seems to work OK, so the fix looks like it may work...

Watch Prototype Failure

Drat! My watch prototype now only ever looks like this:

There's no response to anything and attaching the battery just causes it's voltage to drop to about a volt, which isn't good. I noticed that the battery voltage had started to drop quite quickly a few days ago, but after coming back from a weekend away I found it was completely dead, the battery at a low voltage and no way to resurrect it.

I'm not too surprised, as I was using rechargeable 2032 batteries and they run at 3.6V not 3V, and the PIC16LF707 has a maximum operating voltage of 3.6V. All would be OK, except that the actual voltage of a charged battery is about 4V, so i have been over-volting the part. So in a way there's good news as I know what the problem is. For the PCBs i have some PIC16F707 parts which I will use, they have a maximum operating voltage of 5V so should be OK. I think the power for that part may be a bit higher, but as I'm probably planning to use rechargeable batteries now that shouldn't be a problem. With the display active all hopes of a long battery life go out of the window anyway...

Labels:

diy oled watch,

diy watch,

hardware,

oled watch,

pic,

programming

Thursday, 7 January 2016

More Watch

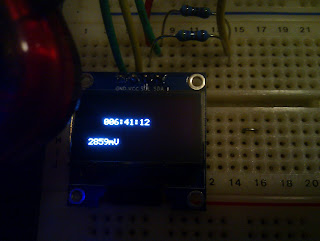

The display is now working, I have functions that display integers and strings and an X-Y positioning function. The display shows text:

The capacitive touch sensors are working too, That's what the OFF OFF means, two sensors are currently off (because I have no finger near the wires). This video shows the capacitive sense inputs in action. You can see OFF swap to ON when I get near the sense wires.

Unfortunately I think the processing of the sense inputs may take up too much current and shorten battery life. I may have to go for the less cool mechanical switches.

Wednesday, 6 January 2016

Watch

The watch firmware now has a basic digital display and a crude analog display.

The display also has a display of battery voltage. The idle loop is now driven by timer 1 in the PIC, which runs from a 32kHz crystal. It keeps pretty good time and also, with a 2s wakeup time should give a reasonable battery life.

The PCB layout was originally going to be a single sided board, but I found it wasn't really practical, and also had problems printing it on my printer so I've decided to do a double sided PCB and have it made elsewhere on the planet.

The layout was pretty simple, we'll see how good it was when the boards come back.

Tuesday, 5 January 2016

Watch

I have to send my watch off every four or five years and am then left with no watch for a while. In the spirit of other making, I've decided to have a go at a watch of my own.

This is a breadboarded circuit using the 40 pin DIP chip. I bought a few of the DIP versions as they are much better for prototyping, I don't want to have to build a PCB at this stage.

The OLED display is here, I have written some simple I2C functions to talk to it and have just sent an initialisation sequence. It's quite a complicated driver and so requires a lot of initialisation just to get to this point. The display pattern is just random RAM data, with some other data written on top.

Friday, 1 January 2016

Oh dear! Broken Phone

My HTC desire had a USB connector problem a few days ago. I sat on the cable and bent it a bit a while back and so when I sat on it again it finally gave up.

Once I had it soldered back on, all was well again, the charging and USB functions worked again:

Subscribe to:

Comments (Atom)