Infrastructure

A bit of tidying up and some infrastructure. First, scrap metal used to be in a slowly collapsing cardboard box. I replaced that with two wooden boxes made out of scrap:

These were quick to make and were made out of dinged wood anyway, so anything the scrap metal does to them is irrelevant. As well as being more sturdy than the cardboard version, they fill the space in the cupboard now:

so they can hold more bits and pieces.

The second thing I made was a tray to fit on the top of my drill press. I had used magnets to hold chuck keys and drill bits, but that was getting to be a bit messy and didn't work that well. I cut some scrap bamboo flooring to the same shape as the top of the drill press belt cover.

To stop the tray moving I 3D printed curved plastic edges that screwed to the flooring.

These stop the tray moving sideways and falling off the drill press. I put a piece of non-slip plastic on top of the drill press, this stops any sliding of the tray and should deaden any rattling when the drill is running.

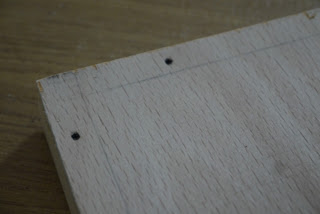

On top of this I put a tray that will hold all the bits an pieces. It's plywood and more scrap,

and it totally screwed together.

How I will arrange what goes in the tray I haven't worked out yet, for now, the chuck keys are in a little area of their own:

I might put a drill index in there somewhere.